OUR

BUSINESS

TECHNICAL SERVICES

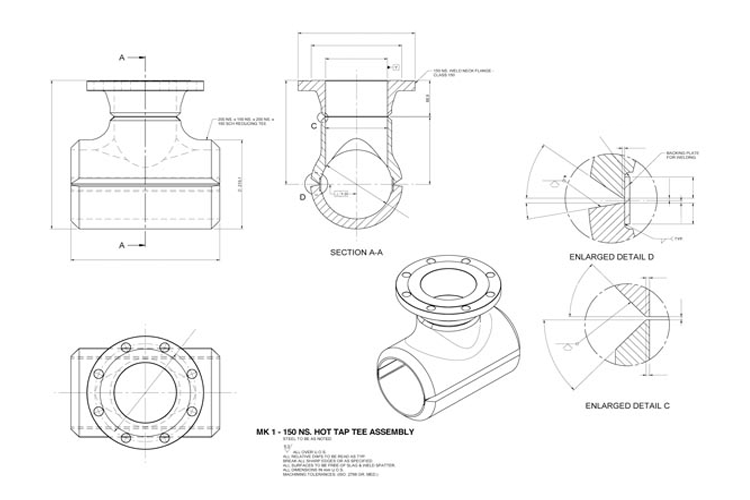

Fabrication

CST is an engineering, manufacturing and supplier of hot tap and line stop full encirclement split tees for the use of hot tapping and line stopping. CST is based in Trichardt Mpumalanga, with regional operations in Portharcourt and Lagos Nigeria.

Design

C.S.T has incorporated a world class design division to meet the growing safety and technological needs of the industries we work in. Our packages include Mechanical Drawings to client specifications, Full QC reports. F.E.A reports. Providing Engineering solutions and the design and fabrication of specialised equipment to overcome obstacles our clients come across in these specialised industries we operate in.

Hot Tapping

C.S.T 29 work to high degree of proficiency, and provide service on 24 hour basis nationwide. Why use Hot Tapping? We use Hot Tappin for the following reasons: Service to consumers process industries and sensitive service is maintained, Contamination / loss of fluid does not occur. Toxic or harmful product is not released. Fire protections are not affected. No time wasted draining the system. Personnel are used efficiently on effecting repair. Eliminates need for bulk transfer and storage of harmful fluids.

Line Stopping

Line stopping can be performed on many types of piping materials and for a variety of media such as gas, water, sewage, oil, nitrogen and most air lines. We perform all activities under pressure, no shutdowns.

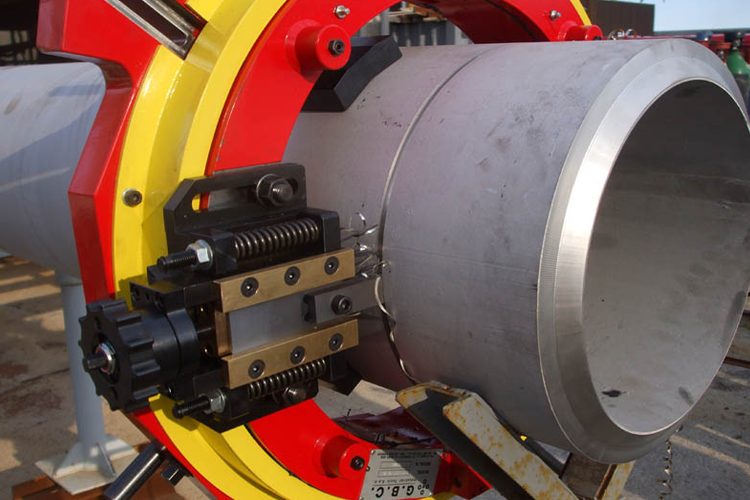

Cold Cutting

A cold cutting procedure is used to cut and/or bevel (prep) pipe work without generating spark, flame or excessive heat. The fact that the procedure generates no flame and/or spark to complete the cut and weld preparation makes it the safest and most cost effective way for abandonment, additions and replacement of pipe work.

Tank Demolition

C.S.T undertook a new challenge in 2011 which we demolished a tank that was 6 meter in diameter and 5 meters tall. C.S.T can proudly say that we successfully completed Cold Cutting the tank in 1.5 meter sections with 2 technicians in 4 days. Advantages of Using C.S.T for Cold Cutting Over Flame Cutting: Safety, No Spark, No Flame, No Air Borne Contamination, No Chance Of Explosion, and Cost Productive.

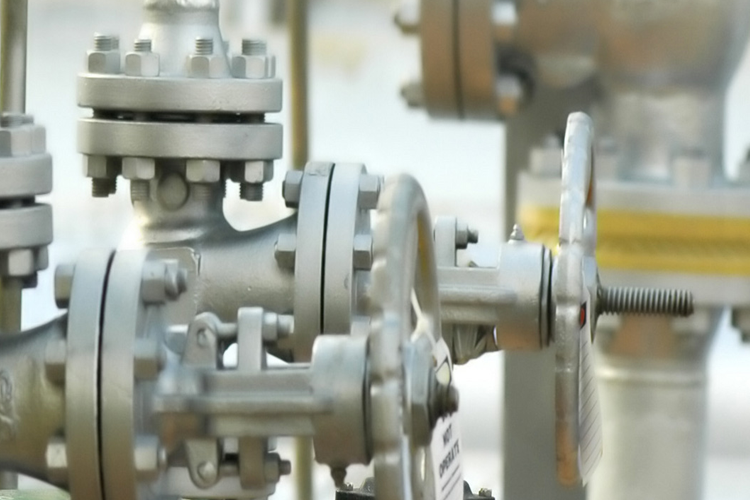

Valve Management

Our aim is to save our clients time and money, by collecting critical data on all their Main Isolation, cross connection, and critical valves across their distribution system. When the problematic valves have been identified we implement our fully automated Valve Exercising procedure on these valves to recover their performance. During the Valve Condition Analysis we also implement a basic exercising procedure. Periodically implementing a basic exercise procedure is critical as part of a successful Valve Management Program.